Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

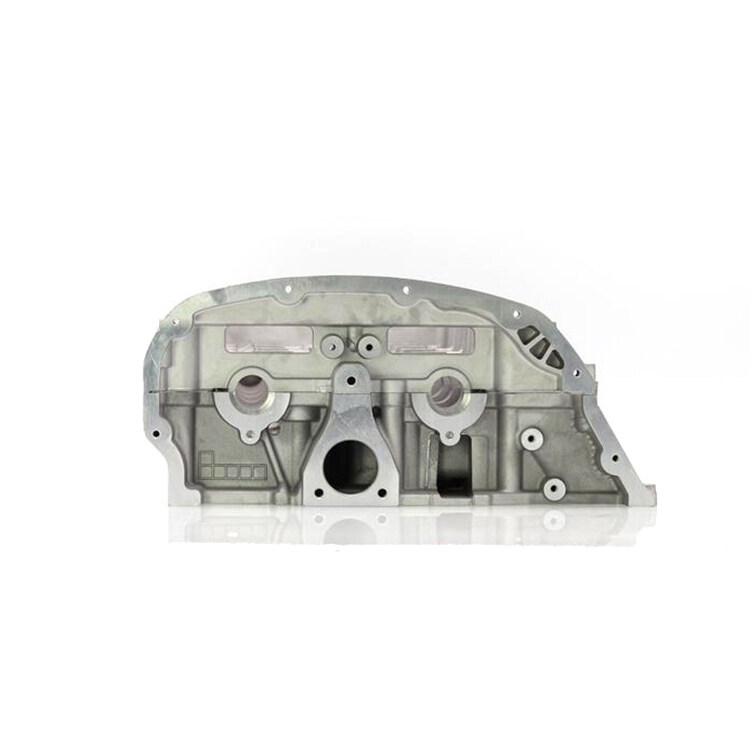

V348 Engine Cylinder Head 1433148 6C1Q-6090-BE 6C1Q-6049

The V1502 Diesel Engine Piston Set is a crucial component used in the Kubota V1502 engine, which is commonly found in various compact industrial and agricultural machinery. The piston set is designed to withstand the demands of diesel engine operation and contributes to efficient power generation.

Features and functions of the V1502 Diesel Engine Piston Set:

-

Materials and Construction: The pistons in the V1502 engine piston set are typically constructed from high-strength materials, such as aluminum alloy or cast iron. These materials are chosen for their durability and heat resistance, ensuring they can withstand the high temperatures and pressures generated during combustion.

-

Ring Grooves: Each piston in the set includes grooves for piston rings. These rings are responsible for creating a seal between the piston and the cylinder walls. Proper sealing prevents the escape of combustion gases, maintains compression, and reduces oil consumption.

-

Crown: The piston crown, located at the top, is designed to withstand the high-temperature environment of the combustion process. It must be heat-resistant and structurally robust.

-

Skirt: The piston skirt is the lower portion that makes contact with the cylinder walls. It helps guide the piston's movement within the cylinder and provides stability during engine operation.

-

Wrist Pin or Piston Pin: The wrist pin, also known as the piston pin, connects the piston to the connecting rod. It allows the piston to pivot and transfers the linear motion of the connecting rod into the rotary motion of the crankshaft.

-

Cooling Features: Some diesel engine pistons, particularly in high-performance engines, may incorporate cooling features, such as oil jets or internal cooling channels, to manage the piston's temperature and prevent overheating.

-

Balanced Weight: Properly balanced piston design ensures that the reciprocating mass is evenly distributed, reducing vibrations and minimizing wear on engine components.

Product Parameter:

|

Product Name |

Cylinder Head |

|

Application |

Excavator, Loader, Bulldozer, Forklift, Trucks, Buses and Others |

|

Engine Number |

V348 |

|

OEM Number |

1433148 / 6C1Q-6090-BE 6C1Q-6049 |

|

Size |

Customized |

|

Condition |

100% Brand-new |

|

Material |

Metal |

|

Payment Way |

T/T, L/C, Paypal, Western Union, UPS |

|

Car Model |

FORD (JMC) |

|

Packing |

Neutral Packing |

The cylinder head of the engine is designed with high-quality sealing to prevent oil and gas leakage, thereby improving the engine’s efficiency and functionality. Despite being lightweight, it is crafted from top-grade materials that significantly enhance its performance, ensuring that it can improve the engine’s reliability and stability. The use of premium materials also allows the cylinder head to withstand high-pressure and high-temperature environments, making it ideal for use in demanding operating conditions.

Advanced Fluid Mechanics:

The cylinder head is designed with advanced fluid mechanics, which optimizes the flow of air and fuel mixture, thereby improving the engine’s combustion efficiency and power output. The cylinder head’s design ensures that the air and fuel mixture flows smoothly and efficiently through the engine’s combustion chamber, reducing turbulence and improving the combustion process. This results in a more complete combustion of the fuel, which translates to improved fuel efficiency and reduced emissions. Additionally, the optimized airflow also enhances the engine’s power output, allowing it to deliver more power with less fuel consumption. The advanced fluid mechanics design of the cylinder head is a testament to the manufacturer’s commitment to delivering high-performance engines that are both efficient and environmentally friendly.

Reliable Manufacture Technology Improves the Engine’s Reliability and Stability:

The cylinder head is manufactured using reliable production processes that ensure each cylinder head meets strict quality and performance standards. The manufacturing process involves the use of advanced technologies and quality control measures to ensure that each cylinder head is crafted to the highest standards of precision and accuracy. This results in a cylinder head that is not only durable and reliable but also performs optimally, enhancing the engine’s reliability and stability. The use of reliable manufacturing processes also ensures that each cylinder head is consistent in terms of quality and performance, providing a high level of uniformity across all engine components. This feature demonstrates the manufacturer’s dedication to providing top-notch engine components that fulfill the requirements of the automotive industry.

Engine internal combustion - a rather complicated unit in terms of technology, consisting of many parts that ensure the well-coordinated operation of the entire mechanism. Some parts perform narrowly technological tasks, others have been given a higher honor - to perform functions leading to the transformation of one type of energy into another, that is, to convert the fuel in the tank into motion energy.

Of the large number of abbreviations that are found on the pages of technical documentation for a car, the abbreviation of the cylinder head is probably the most common. Why and what is a cylinder head in a car worth finding out more.

How is the cylinder head deciphered

The abbreviation for cylinder head stands for simple. This is the cylinder head - a part that can be attributed to one of the most important in the entire internal combustion engine as a whole. It is this unit that controls the fuel combustion process and is responsible for the removal of spent elements outside, in in this case gases. To better understand what a cylinder head is in a car engine, you need to consider its design in detail and disassemble its main functions.

Design features of the cylinder head and its constituent parts

For a long time, cylinder heads were made of cast iron, which is now being abandoned in favor of products from light alloys of metals on an aluminum base. Aluminum cylinder heads are used more and more often, but cast-iron heads cannot be completely abandoned. There are types of engines where the temperature operating regime does not allow the use of a light alloy, since there is a high risk of thermal shrinkage and deformation, and cast iron heads are most effectively resisted to such processes.

The cylinder head is superimposed on the cylinder from above and is attached to its base with bolts or studs (the type of attachment depends on the engine modification and the address of its manufacture). The landing plane of the head is large enough in area, therefore, in order to avoid deformation of the structure during fastening, a certain sequence is used, the sequence of tightening each threaded connection, and some effort. The fastening scheme and the sequence of tightening the connections for each engine is developed individually, which is due to the difference in design solutions.

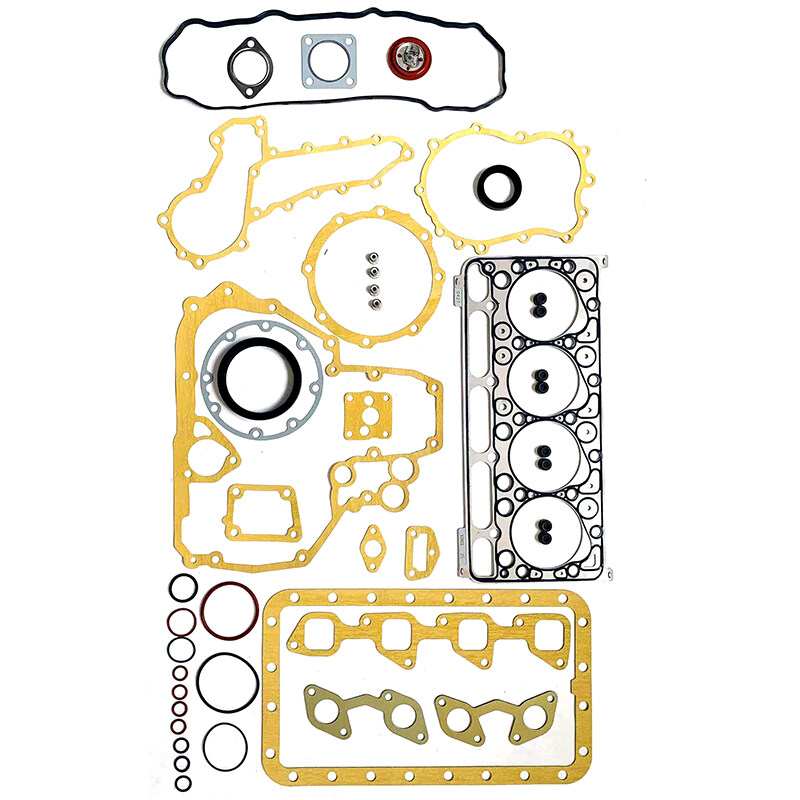

In so-called in-line engines, one block head covers the entire cylinder body, and in engines where the cylinders are arranged in a V-shape, each row has its own block head. To ensure an effective tightness of the connection between the cylinder and the head, a gasket is placed, which has the exact shape of the head and cylinder, and all the necessary mounting holes. The gaskets are made of reinforced asbestos sheet, which is a refractory material and, regardless of the heating level, maintains the tightness of the combustion chamber.

For more information about V348 Cylinder Head, please kindly contact us at any time, we are glad to answer for you. If you want to order in quantity, hope that we will be your best choice.